A production layout guide is a comprehensive document that helps businesses optimize factory operations by mapping workflows, ensuring safety, and maximizing efficiency. It provides a clear blueprint for organizing equipment, processes, and spaces to enhance productivity and reduce costs.

1.1 Understanding the Importance of Production Layout

A well-designed production layout optimizes efficiency, reduces operational costs, and enhances safety. It streamlines workflows, improves resource allocation, and supports lean manufacturing principles. A structured layout ensures smooth production processes, minimizes downtime, and maximizes space utilization, ultimately boosting productivity and competitiveness in manufacturing environments.

1.2 Overview of the Production Layout Guide

This guide provides a structured approach to designing and optimizing production layouts. It covers key principles, types of layouts, and practical steps for implementation. The guide also addresses tools, best practices, and future trends, offering a comprehensive resource for businesses aiming to enhance efficiency, safety, and sustainability in their manufacturing facilities.

Types of Production Layouts

Production layouts are categorized into three primary types: process layouts, product layouts, and fixed layouts. Each type is designed to optimize workflow based on specific production requirements and goals.

2.1 Process Layout

A process layout organizes similar equipment or functions into dedicated areas, enabling efficient handling of varied production lines. This setup minimizes downtime and optimizes resource utilization, making it ideal for industries with diverse product ranges or frequent design changes. It supports Lean principles by reducing waste and enhancing flexibility in manufacturing processes.

2.2 Product Layout

A product layout arranges machinery and workstations in a sequential flow to produce a specific product. This layout streamlines production, reduces lead times, and enhances workflow efficiency. It is typically used for standardized products, ensuring smooth material flow and minimizing handling costs, while promoting specialization among workers. This setup is ideal for high-volume manufacturing operations aiming for consistency and precision.

2.3 Fixed Layout

A fixed layout involves positioning a central, often large or immobile piece of equipment or machinery. Other processes and workstations are arranged around it, optimizing workflow for specific tasks. This layout is commonly used in industries like aerospace or shipbuilding, where the product remains stationary, and resources are brought to it, ensuring efficiency in handling large-scale or complex production processes.

Key Factors in Production Layout Design

Workflow analysis, space utilization, safety, and efficiency are critical factors in designing a production layout. Proper planning ensures optimal resource allocation, reduces waste, and enhances overall productivity.

3.1 Workflow and Process Analysis

Workflow and process analysis involves mapping each production step to identify inefficiencies and optimize the sequence of operations. By understanding how materials, information, and tasks flow, businesses can streamline processes, reduce bottlenecks, and improve productivity, ensuring a logical and efficient layout design that aligns with production goals and operational needs.

3.2 Space Utilization and Efficiency

Efficient space utilization ensures that every area within the facility contributes to productivity. By optimizing the arrangement of machinery, workstations, and storage, companies can minimize waste, reduce movement costs, and improve workflow. Proper space planning also enhances safety and accessibility, ensuring a well-organized and functional environment that supports operational efficiency and scalability;

3.3 Safety and Ergonomic Considerations

Safety and ergonomics are critical in production layout design. Ensuring clear pathways, proper lighting, and hazard-free zones minimizes accidents. Ergonomic workstations reduce employee fatigue and injuries, promoting long-term well-being. Compliance with safety standards and regulations is essential to create a secure and efficient working environment that supports both worker health and operational effectiveness.

Steps to Create an Effective Production Layout

Creating an effective production layout involves understanding requirements, designing a detailed plan, and implementing it efficiently to optimize workflow, safety, and productivity while minimizing costs and ensuring scalability.

4.1 Assessing Production Requirements

Assessing production requirements involves understanding workflows, product volumes, and operational objectives. This step ensures the layout aligns with production goals, optimizes space, and integrates necessary equipment, fostering efficiency and scalability.

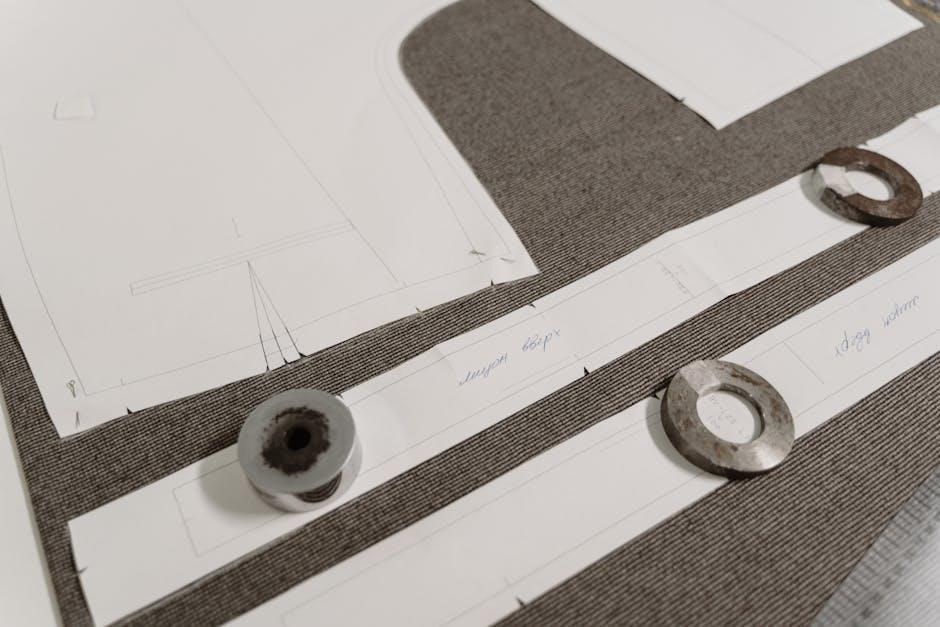

4.2 Developing a Detailed Layout Plan

Creating a detailed layout plan involves mapping workflows, positioning equipment, and defining zones for efficiency. It ensures logical placement of machinery, minimizes bottlenecks, and enhances safety, creating a blueprint for smooth operations and scalability.

4.3 Implementing and Testing the Layout

Implementation involves executing the layout design, ensuring all components are correctly positioned; Testing evaluates efficiency, safety, and workflow. Adjustments are made based on feedback to optimize operations, ensuring the layout meets production goals and adapts to future needs effectively.

Tools and Software for Production Layout Planning

Tools and software like CAD and simulation programs are essential for designing efficient production layouts, ensuring safety, and optimizing workflows. They help visualize and test layouts before implementation.

5.1 CAD Software for Layout Design

CAD software is a powerful tool for creating detailed production layouts. It allows designers to draft precise floor plans, arrange equipment, and simulate workflows. Features like 2D and 3D modeling enable visualization of the factory setup, ensuring optimal space utilization and efficient material flow. CAD also supports collaboration and iterative design improvements, making it indispensable for modern manufacturing planning.

5.2 Simulation Tools for Workflow Optimization

Simulation tools enable virtual testing and analysis of production workflows, helping identify inefficiencies and optimize layouts. They allow real-time adjustments, reduce implementation costs, and enhance productivity by ensuring smooth operations. These tools provide data-driven insights, making them essential for streamlining manufacturing processes and achieving operational excellence in factory design and workflow planning.

Best Practices for Optimizing Production Layout

Optimizing production layout requires adopting best practices, focusing on lean principles to eliminate waste and improve workflows. Continuous improvement strategies ensure ongoing efficiency and adaptability.

6.1 Lean Principles in Layout Design

Lean principles emphasize minimizing waste and maximizing value in layout design. By focusing on efficient workflows, reducing unnecessary movement, and optimizing space, businesses can improve productivity and reduce operational costs. These principles help create a streamlined environment that supports continuous improvement and adapts to changing production needs effectively.

6.2 Continuous Improvement Strategies

Continuous improvement strategies involve regularly assessing and refining the production layout to enhance efficiency and adapt to new challenges. This includes gathering feedback, monitoring performance metrics, and implementing incremental changes. By fostering a culture of ongoing optimization, businesses can maintain a competitive edge and ensure their layout remains aligned with evolving production needs and technological advancements.

Case Studies and Examples of Successful Layouts

Real-world applications of effective layouts demonstrate how optimized production designs enhance efficiency and productivity. These examples highlight key principles and provide insights for implementing successful layout strategies in various industries.

7.1 Real-World Applications of Effective Layouts

Manufacturing facilities worldwide have successfully implemented lean layouts, reducing waste and boosting efficiency. For instance, automotive plants use product layouts to streamline assembly lines, while tech companies apply process layouts for modular production. These real-world examples illustrate how tailored layouts can significantly enhance operational performance and adaptability in diverse industrial settings.

7.2 Lessons Learned from Successful Implementations

Successful layouts emphasize continuous training, ensuring teams adapt to new workflows. Lean principles minimize waste, while detailed workflow analysis prevents bottlenecks. Involving employees fosters ownership, and scalable designs accommodate growth. Technology integration enhances efficiency, making layouts future-ready. These insights highlight best practices for achieving long-term operational success and adaptability in manufacturing environments;

Future Trends in Production Layout Design

Future trends emphasize automation, smart technologies, and sustainability. These innovations enable efficient, eco-friendly factories, optimizing workflows and reducing environmental impact while boosting productivity and adaptability.

8.1 Integration of Automation and Technology

The integration of automation and technology in production layouts is revolutionizing factory design. Advanced systems, such as robotics and IoT devices, optimize workflows, reduce downtime, and enhance sustainability. These technologies enable real-time monitoring and data-driven decisions, ensuring efficient resource allocation and continuous improvement in manufacturing processes. This leads to smarter, more adaptable factories.

8.2 Sustainability and Green Factory Layouts

Sustainable production layouts prioritize energy efficiency, waste reduction, and eco-friendly practices. Green factories incorporate renewable resources, recycled materials, and energy-saving technologies. Layouts are designed to minimize environmental impact while maintaining productivity. This approach supports long-term operational savings and aligns with global environmental standards, fostering a responsible and future-ready manufacturing environment.

Common Mistakes to Avoid in Production Layout

Common mistakes include poor space utilization, ignoring workflow efficiency, and inadequate safety planning. These errors can lead to operational bottlenecks, increased costs, and reduced productivity.

9.1 Pitfalls in Initial Planning Phases

Initial planning pitfalls include inadequate assessment of production requirements, poor workflow analysis, and insufficient consideration of future scalability; These oversights can lead to inefficient layouts, increased operational costs, and difficulty adapting to changes, ultimately affecting overall productivity and employee safety. Proper research and stakeholder involvement are crucial to avoid these common mistakes.

9.2 Errors in Execution and Implementation

Execution errors often arise from poor communication, inadequate training, and insufficient testing of the layout. These mistakes can result in workflow bottlenecks, safety hazards, and equipment inefficiencies. Additionally, failing to involve key stakeholders during implementation can lead to resistance to change, further complicating the transition to the new production layout and reducing its effectiveness.

A well-designed production layout is crucial for optimizing efficiency, safety, and productivity. Continuous learning and adaptation ensure sustainable success in evolving manufacturing environments.

10.1 Summarizing Key Takeaways

Efficient production layouts enhance workflow, safety, and productivity while reducing costs. Key principles include optimizing space, integrating technology, and adopting lean practices. Continuous improvement ensures long-term success and adaptability to industry trends.

- Optimize workflows for efficiency and safety.

- Leverage technology and automation.

- Adopt lean principles for waste reduction.

- Focus on sustainability and scalability.

- Encourage ongoing learning and adaptation.

10.2 Encouraging Continuous Learning and Adaptation

Continuous learning fosters innovation and adaptability in production layouts. Encourage teams to stay updated on industry trends, adopt new tools, and share knowledge. Regular training and cross-functional collaboration ensure a workforce ready to evolve with changing demands and technologies.

- Promote ongoing training and upskilling.

- Encourage knowledge sharing across teams.

- Stay updated on industry advancements.

- Foster a culture of innovation.

- Adapt workflows to new technologies.